Let us introduce production process of soft iron forging club head, which is Zodia’s signature product.

Forged soft iron head arrives

After blocking, proceed deburring and then do finish forging again.

Engrave count numbers on sole

Weight Adjustment

Smoothing treatment by CNC

Make the face, grinded by grinder, even more accurate and smoother by NC processor.

Score line stamp

Stamp the score line with even thickness and width on face, which smoothened by processor.

Loft and lie angle adjustment

Generally it is adjusted by bending, but at Zodia, Chiba adjusts by hammering. By this process, it is nudged to more natural curve.

Cavity CNC process

Design of back face is proceeded by three dimensional process.

Engraving stamp

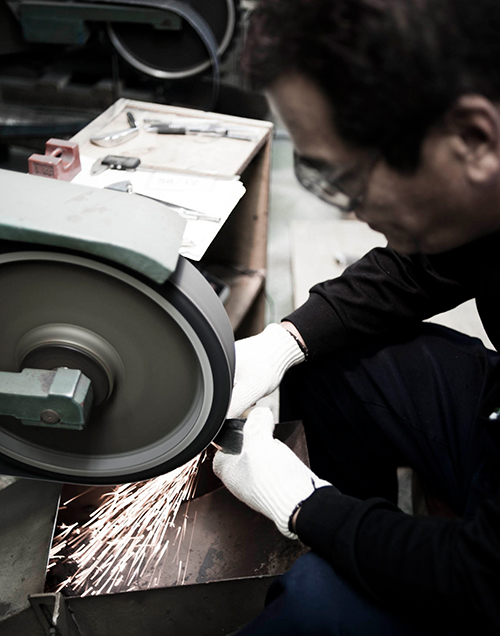

Grinding

It is finished to become Zodia head by Chiba’s daring but delicate technique.

Completion

Then finally complete after coloring and final inspection. As it shows, Zodia’s club implemented inimitable quality, which cannot be done by mass production, by Chiba himself does most of the processes and spend a long time creating.